Hydraulic Brake System in a Car

Introduction

The hydraulic brake system is one of the most important safety features in a car. It allows the driver to control the vehicle’s speed and stop it when necessary. The system consists of a series of interconnected components that work together to create hydraulic pressure, which is then used to actuate the brakes.

Components of the Hydraulic Brake System

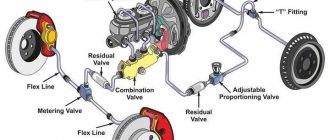

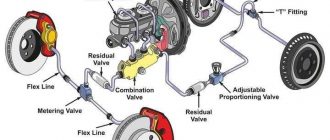

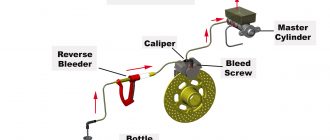

The main components of the hydraulic brake system are:

– **Master cylinder:** The master cylinder is the heart of the hydraulic brake system. It converts the force applied to the brake pedal into hydraulic pressure. When a force is applied to the brake pedal, the master cylinder moves a piston, which creates pressure in the brake fluid.

– **Brake lines:** The brake lines carry the brake fluid from the master cylinder to the wheels. They are made of steel or flexible rubber tubing.

– **Brake calipers:** The brake calipers are mounted on the wheels and contain the brake pads. When hydraulic pressure is applied to the brake calipers, the brake pads are forced against the rotors, which slows the vehicle down.

– **Brake rotors:** The brake rotors are mounted on the wheels and provide a surface for the brake pads to rub against. They are made of cast iron or steel.

– **Brake fluid:** Brake fluid is a hydraulic fluid that is used to transmit pressure from the master cylinder to the brake calipers. It is typically made of glycol ethers and has a high boiling point.

How the Hydraulic Brake System Works

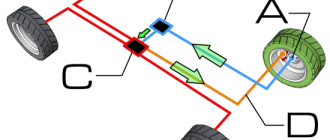

When the driver presses on the brake pedal, the master cylinder converts the force into hydraulic pressure in the brake fluid. The brake fluid then flows through the brake lines to the brake calipers, where it applies pressure to the brake pads. The brake pads rub against the brake rotors, which slows the vehicle down.

The amount of pressure applied to the brake pads determines the amount of braking force that is generated. The harder the driver presses on the brake pedal, the more pressure is applied to the brake pads and the greater the braking force.

Maintenance of the Hydraulic Brake System

The hydraulic brake system is a complex system that requires regular maintenance to ensure that it is functioning properly. Some of the most important maintenance tasks include:

– **Checking the brake fluid level:** The brake fluid level should be checked regularly and topped up as needed. Low brake fluid levels can lead to reduced braking performance and may indicate a leak in the system.

– **Bleeding the brakes:** Bleeding the brakes removes air bubbles from the system. Air bubbles can cause the brake pedal to feel spongy and reduce braking performance.

– **Replacing the brake pads:** Brake pads wear out over time and need to be replaced periodically. Worn brake pads can reduce braking performance and may cause damage to the brake rotors.

– **Replacing the brake rotors:** Brake rotors also wear out over time and need to be replaced periodically. Worn brake rotors can cause the brake pads to wear out more quickly and may reduce braking performance.

Conclusion

The hydraulic brake system is a vital safety feature in a car. It is important to understand how the system works and to perform regular maintenance to ensure that it is functioning properly.