Hand Brake System Train Car

Introduction

A hand brake is a device used to manually apply the brakes on a train car. It is typically used in the event of a brake system failure or to hold the train in place when it is not moving. Hand brakes can be either mechanical or hydraulic.

Mechanical Hand Brakes

Mechanical hand brakes use a system of levers and cables to apply the brakes. The hand brake lever is located in the cab of the locomotive or caboose. When the lever is pulled, it activates a series of levers and cables that pull on the brake shoes, which in turn apply pressure to the wheels.

Mechanical hand brakes are simple and reliable, but they can be difficult to operate. The amount of force required to pull the lever can vary depending on the weight of the train and the condition of the brake system.

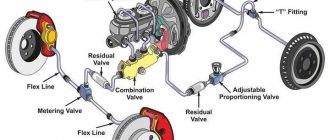

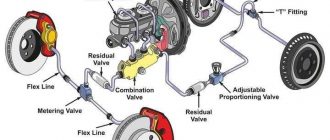

Hydraulic Hand Brakes

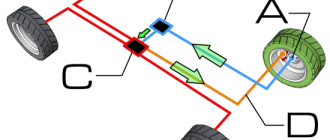

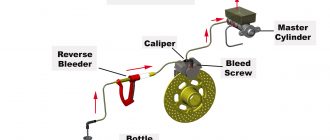

Hydraulic hand brakes use a hydraulic system to apply the brakes. The hand brake lever is connected to a hydraulic pump, which pressurizes the hydraulic fluid. The hydraulic fluid is then sent to the brake cylinders, which in turn apply pressure to the brake shoes.

Hydraulic hand brakes are easier to operate than mechanical hand brakes, but they are more complex and expensive. Hydraulic hand brakes are also more susceptible to leaks, which can lead to a loss of braking power.

Dual Hand Brakes

Some train cars are equipped with dual hand brakes. This provides redundancy in the event of a brake system failure. If one hand brake fails, the other hand brake can be used to stop the train.

Operation

To apply the hand brake, the operator pulls on the hand brake lever. The lever is typically located in the cab of the locomotive or caboose. When the lever is pulled, it activates a series of levers and cables that pull on the brake shoes. The brake shoes are pressed against the wheels, which slows down the train.

To release the hand brake, the operator pushes on the hand brake lever. The lever is typically located in the cab of the locomotive or caboose. When the lever is pushed, it releases the levers and cables that pull on the brake shoes. The brake shoes are released from the wheels, which allows the train to move freely.

Inspection and Maintenance

Hand brakes should be inspected and maintained regularly to ensure that they are in good working order. The inspection should include a check of the levers, cables, and brake shoes. The brake shoes should be replaced if they are worn or damaged.

Conclusion

Hand brakes are an important part of the train brake system. They provide a backup in the event of a brake system failure and can be used to hold the train in place when it is not moving. Hand brakes can be either mechanical or hydraulic. Mechanical hand brakes are simple and reliable, but they can be difficult to operate. Hydraulic hand brakes are easier to operate, but they are more complex and expensive. Dual hand brakes provide redundancy in the event of a brake system failure.