Gas RC Car Brake System

Introduction

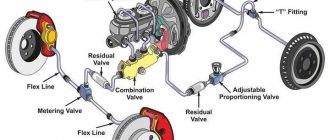

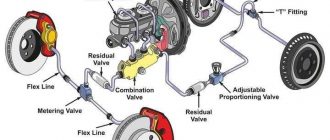

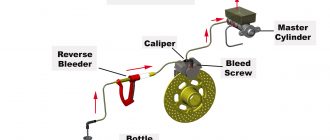

The brake system in a gas RC car is responsible for slowing down and stopping the vehicle. It consists of several components, including the brake pads, brake discs, brake calipers, and brake master cylinder. When the driver presses the brake pedal, the brake master cylinder sends brake fluid to the brake calipers, which in turn squeeze the brake pads against the brake discs. This creates friction, which slows down and stops the vehicle.

Types of Brake Systems

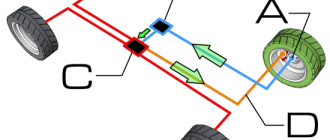

There are two main types of brake systems used in gas RC cars: disc brakes and drum brakes.

- Disc brakes are the most common type of brake system used in gas RC cars. They consist of a brake disc that is mounted to the wheel hub and a brake caliper that is mounted to the suspension. When the brake pedal is pressed, the brake caliper squeezes the brake pads against the brake disc, which slows down and stops the vehicle.

- Drum brakes are less common than disc brakes in gas RC cars. They consist of a brake drum that is mounted to the wheel hub and a brake shoe that is mounted to the brake backing plate. When the brake pedal is pressed, the brake shoe presses against the brake drum, which slows down and stops the vehicle.

Components of a Brake System

The brake system in a gas RC car consists of several components, including:

- Brake pads are the components that come into contact with the brake discs and create friction. They are typically made of a composite material that can withstand high temperatures and wear.

- Brake discs are the components that are attached to the wheel hubs and provide a surface for the brake pads to grip. They are typically made of a metal alloy that can withstand high temperatures and wear.

- Brake calipers are the components that house the brake pads and apply pressure to them when the brake pedal is pressed. They are typically made of a lightweight metal alloy.

- Brake master cylinder is the component that sends brake fluid to the brake calipers when the brake pedal is pressed. It is typically made of a lightweight metal alloy.

How a Brake System Works

When the driver presses the brake pedal, the brake master cylinder sends brake fluid to the brake calipers. The brake calipers then squeeze the brake pads against the brake discs, which creates friction. This friction slows down and stops the vehicle.

Maintenance of a Brake System

The brake system in a gas RC car requires regular maintenance to ensure that it is functioning properly. This maintenance includes:

- Checking the brake pads for wear. The brake pads should be replaced when they are worn down to 1/4 inch or less.

- Checking the brake discs for wear. The brake discs should be replaced when they are warped or cracked.

- Checking the brake fluid level. The brake fluid level should be checked regularly and topped off as needed.

- Bleeding the brake system. The brake system should be bled regularly to remove any air from the system.

Troubleshooting a Brake System

If the brake system in a gas RC car is not functioning properly, there are several things that can be done to troubleshoot the problem.

- Check the brake pads for wear. If the brake pads are worn down to 1/4 inch or less, they should be replaced.

- Check the brake discs for wear. If the brake discs are warped or cracked, they should be replaced.

- Check the brake fluid level. If the brake fluid level is low, it should be topped off.

- Bleed the brake system. If the brake system has air in it, it should be bled.

Conclusion

The brake system in a gas RC car is an important component that ensures that the vehicle can be stopped safely. By understanding how the brake system works and how to maintain it, you can help ensure that your RC car is always ready to race.