##

### Introduction

In the high-stakes world of racing, braking performance is crucial for safety, lap times, and overall competitiveness. Designing an effective brake system for a race car requires a deep understanding of the physics involved, as well as the specific demands of the racing discipline and circuit characteristics. This article will delve into the essential aspects of race car brake system design, providing valuable insights for engineers and racers alike.

### Brake System Requirements

The primary function of a race car brake system is to:

* **Slow down the vehicle:** Decelerate the car from high speeds in a controlled and efficient manner.

* **Control cornering:** Provide precise modulation to regulate the car’s speed and balance in corners.

* **Prevent fade:** Withstand repeated and intense braking without losing effectiveness.

### Key Components

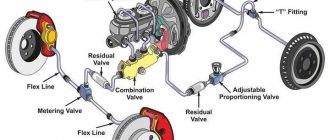

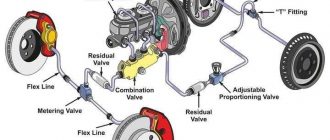

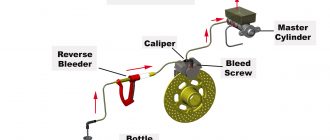

A race car brake system consists of the following main components:

* **Brake pedal:** Initiates braking by activating the master cylinder.

* **Master cylinder:** Converts pedal force into hydraulic pressure.

* **Brake lines:** Transmit hydraulic pressure to the calipers.

* **Calipers:** House the brake pads that clamp onto the rotors.

* **Brake rotors:** Rotating discs that generate friction against the brake pads.

* **Brake pads:** Provide friction against the rotors, generating heat and stopping the car.

### Rotor Design

The design of the brake rotors is critical for heat dissipation, cooling efficiency, and resistance to warping. Common rotor designs include:

* **Vented rotors:** Feature channels between the rotor faces to allow airflow and dissipate heat.

* **Drilled rotors:** Have holes drilled through the rotor to provide additional cooling but may weaken the rotor.

* **Cross-drilled and slotted rotors:** Combine both venting and drilling to maximize heat dissipation and friction surface area.

### Caliper Design

Brake calipers are typically made of aluminum or steel and house the brake pads. They must be designed to withstand high temperatures, provide precise pad actuation, and prevent heat-induced deformation.

* **Fixed calipers:** Pads are pressed onto the rotor from one side, providing increased rigidity and heat dissipation.

* **Floating calipers:** Pads are mounted on a bracket that floats with the rotor, allowing for thermal expansion and reducing brake drag.

### Brake Pad Materials

Brake pad materials play a significant role in brake performance and durability. Common materials used in race car applications include:

* **Organic pads:** Made from non-metallic compounds, offering low noise and fade resistance but less aggressive initial bite.

* **Ceramic pads:** Formulated with ceramic fibers, providing high durability, fade resistance, and less rotor wear.

* **Metallic pads:** Contain metal particles, offering aggressive bite, high heat capacity, and longer lifespan.

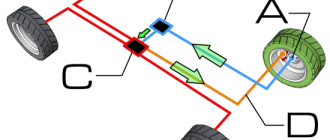

### Brake Bias

Brake bias refers to the distribution of braking force between the front and rear wheels. It is adjusted to suit the car’s handling and stability characteristics.

* **Front bias:** Provides more braking power to the front wheels, resulting in better turn-in response and reduced understeer.

* **Rear bias:** Shifts braking power towards the rear, stabilizing the car under braking and reducing oversteer.

### Auxiliary Systems

In addition to the core components, race car brake systems often incorporate auxiliary systems to enhance performance and safety. These include:

* **Brake cooling ducts:** Direct airflow to the rotors and calipers to dissipate heat and reduce fade.

* **Brake boosters:** Amplify pedal force, reducing driver fatigue and improving braking power.

* **Anti-lock brake systems (ABS):** Prevent wheel lockup during hard braking, enhancing control and stability.

### Design Considerations

When designing a race car brake system, engineers must consider several critical factors:

* **Aerodynamic downforce:** Downforce generated by the car’s aerodynamics affects tire grip and braking performance.

* **Tire characteristics:** Tire choice and condition significantly influence brake system effectiveness.

* **Track conditions:** Surface grip levels vary depending on the track environment, affecting braking distances and heat buildup.

* **Car weight and weight distribution:** The weight and balance of the car impact braking force and stability.

* **Driver preference:** Driver feedback and input can help optimize brake system response and balance.

### Conclusion

Designing a race car brake system is a complex and demanding task that requires careful consideration of various factors. By understanding the physics of braking, the specific requirements of the racing discipline, and the available technologies, engineers can develop systems that deliver exceptional performance, safety, and competitive advantage. Continuous testing, data analysis, and feedback loops are crucial for perfecting and optimizing brake system designs to meet the ever-evolving demands of the racing environment.