**Old Train Car Brake Lever System**

**Introduction**

Before the advent of sophisticated air brake systems, railroads relied on manual braking mechanisms to stop their trains. One of the most common systems was the hand brake, which utilized a lever-operated mechanism to apply brake shoes to the wheels. Understanding the intricacies of this old train car brake lever system is essential for appreciating the historical evolution of braking technology.

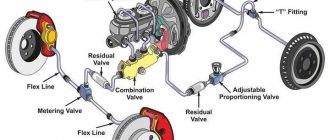

### **Components of the Brake Lever System**

The hand brake lever system comprised several key components:

1. **Brake Lever:** A long, metal lever handle located in the brake van or locomotive cab.

2. **Brake Chain:** A heavy chain that connected the brake lever to the brake rigging underneath the car.

3. **Brake Rigging:** A series of levers and rods that transmitted the force from the brake lever to the brake shoes.

4. **Brake Shoes:** Cast iron or composite blocks that pressed against the wheels to create friction and slow the train.

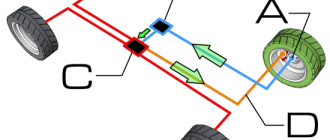

### **Operation of the Brake Lever System**

Applying the hand brake involved the following steps:

1. The brakeman pulled down on the brake lever.

2. The brake chain pulled the brake rigging, causing the brake shoes to be forced against the wheels.

3. Friction between the shoes and wheels generated heat and slowed the train.

### **Advantages and Disadvantages**

The hand brake lever system offered several advantages:

* **Simplicity:** The system was mechanically straightforward and easy to maintain.

* **Reliability:** It was a robust system that rarely failed, even in harsh conditions.

* **Control:** Brakemen had direct control over the braking force, allowing for precise speed modulation.

However, the system also had some disadvantages:

* **Labor-Intensive:** Manually applying the brakes required significant effort, especially on long trains.

* **Limited Braking Power:** The braking force was limited by the strength of the brakeman operating the lever.

* **Slow Response Time:** The system had a relatively slow response time, making it less effective for emergency braking.

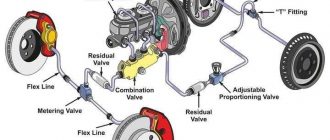

### **Evolution and Replacement**

With the increase in train speeds and the need for more powerful braking systems, the hand brake lever system gradually fell out of favor. Air brakes, which utilized compressed air to actuate brake cylinders, emerged as the standard braking technology for railroads. Air brakes offered faster response times, greater braking power, and could be controlled from the locomotive, eliminating the need for brakemen to operate levers throughout the train.

### **Conclusion**

The old train car brake lever system played a crucial role in the development of railroad transportation. Its simplicity, reliability, and operator control made it an effective solution for early railroads. However, as technology advanced, air brakes surpassed its limitations, contributing to the safety and efficiency of modern trains. Understanding the intricacies of this historical braking system provides a glimpse into the evolution of railroad engineering and the challenges faced by early railroad operators.