Hydraulic Car Brake System

Introduction

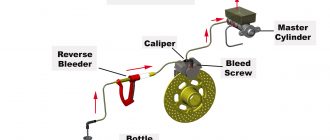

A hydraulic car brake system is a system that uses hydraulic fluid to transfer the force from the brake pedal to the brake pads. The hydraulic fluid is contained in a master cylinder, which is connected to the brake pedal. When the brake pedal is depressed, the master cylinder forces the hydraulic fluid through brake lines to the brake calipers. The brake calipers then use the hydraulic fluid to apply pressure to the brake pads, which in turn apply pressure to the brake rotors. This causes the brake rotors to slow down and stop the car.

Components of a Hydraulic Car Brake System

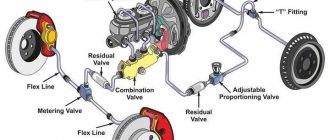

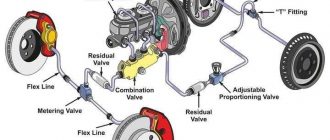

The main components of a hydraulic car brake system include:

* Master cylinder

* Brake lines

* Brake calipers

* Brake pads

* Brake rotors

Master Cylinder

The master cylinder is the heart of the hydraulic car brake system. It is a cylindrical-shaped component that is mounted on the firewall of the car. The master cylinder contains a piston that is connected to the brake pedal. When the brake pedal is depressed, the piston moves forward and forces the hydraulic fluid through the brake lines.

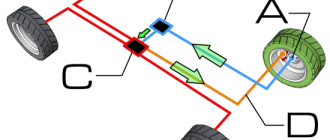

Brake Lines

The brake lines are the tubes that carry the hydraulic fluid from the master cylinder to the brake calipers. The brake lines are made of a strong and flexible material, such as stainless steel or rubber.

Brake Calipers

The brake calipers are the components that apply pressure to the brake pads. The brake calipers are mounted on the wheels of the car. Each brake caliper contains a piston that is connected to the brake pads. When the hydraulic fluid is forced into the brake caliper, the piston moves forward and applies pressure to the brake pads.

Brake Pads

The brake pads are the components that actually stop the car. The brake pads are made of a friction material, such as ceramic or organic. When the brake pads are pressed against the brake rotors, they create friction that slows down and stops the car.

Brake Rotors

The brake rotors are the discs that the brake pads rub against to slow down and stop the car. The brake rotors are made of a hard and durable material, such as cast iron or steel.

How a Hydraulic Car Brake System Works

When the brake pedal is depressed, the piston in the master cylinder moves forward and forces the hydraulic fluid through the brake lines. The hydraulic fluid then travels to the brake calipers, where it forces the pistons in the brake calipers to move forward. The pistons in the brake calipers then apply pressure to the brake pads, which in turn apply pressure to the brake rotors. This causes the brake rotors to slow down and stop the car.

Advantages of a Hydraulic Car Brake System

There are several advantages to using a hydraulic car brake system, including:

* Power: Hydraulic car brake systems are very powerful, which allows them to stop a car quickly and efficiently.

* Responsiveness: Hydraulic car brake systems are very responsive, which means that they can stop a car quickly and smoothly.

* Reliability: Hydraulic car brake systems are very reliable, which means that they are unlikely to fail.

Disadvantages of a Hydraulic Car Brake System

There are also some disadvantages to using a hydraulic car brake system, including:

* Cost: Hydraulic car brake systems are relatively expensive to purchase and maintain.

* Complexity: Hydraulic car brake systems are relatively complex, which means that they can be difficult to repair.

* Weight: Hydraulic car brake systems are relatively heavy, which can reduce the fuel efficiency of a car.

Conclusion

Hydraulic car brake systems are a powerful, responsive, and reliable way to stop a car. However, they are also relatively expensive, complex, and heavy.