## Drag Race Car Brake System Design

### Introduction

Drag racing is a high-speed sport that requires cars to accelerate and decelerate quickly and efficiently. The braking system is a critical component of a drag race car, as it must be able to stop the car quickly and safely at the end of the race.

### Design Considerations

When designing a drag race car brake system, there are a number of factors that must be taken into consideration, including:

* **Weight:** The weight of the brake system must be minimized, as it will reduce the car’s overall performance.

* **Strength:** The brake system must be strong enough to withstand the high forces that are generated during braking.

* **Durability:** The brake system must be durable enough to withstand the repeated use that it will be subjected to.

* **Cost:** The brake system must be affordable to build and maintain.

### Types of Brake Systems

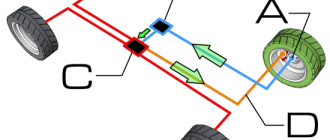

There are two main types of brake systems used in drag race cars:

* **Mechanical brake systems:** Mechanical brake systems use a pedal to apply pressure to a master cylinder, which in turn applies pressure to the brake pads. Mechanical brake systems are simple and reliable, but they can be heavy and difficult to adjust.

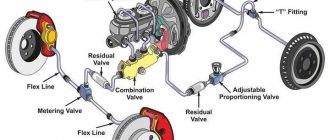

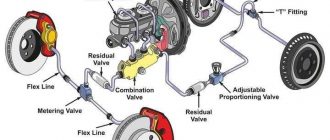

* **Hydraulic brake systems:** Hydraulic brake systems use a fluid to transmit pressure from the master cylinder to the brake pads. Hydraulic brake systems are more efficient than mechanical brake systems, and they can be lighter and easier to adjust.

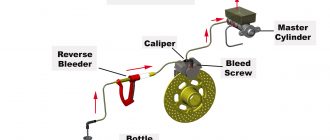

### Brake Components

The main components of a drag race car brake system include:

* **Brake pads:** Brake pads are the friction material that contacts the brake rotors to slow the car down. Brake pads are typically made of a composite material, such as carbon fiber or ceramic.

* **Brake rotors:** Brake rotors are the metal discs that the brake pads contact to slow the car down. Brake rotors are typically made of steel or aluminum.

* **Calipers:** Calipers are the devices that hold the brake pads in place and apply pressure to them. Calipers are typically made of aluminum or steel.

* **Master cylinder:** The master cylinder is the device that converts the force applied to the brake pedal into hydraulic pressure. Master cylinders are typically made of aluminum or steel.

* **Brake lines:** Brake lines are the tubes that carry the brake fluid from the master cylinder to the calipers. Brake lines are typically made of rubber or stainless steel.

### Brake System Design

The design of a drag race car brake system will vary depending on the specific car and the type of racing that it will be used for. However, there are some general principles that can be applied to all drag race car brake systems.

* **The brake system should be designed to provide the maximum amount of stopping power possible.** This means using large brake pads and rotors, and using a high-performance brake fluid.

* **The brake system should be designed to be lightweight.** This means using lightweight materials, such as aluminum and carbon fiber.

* **The brake system should be designed to be durable.** This means using high-quality materials and components, and properly maintaining the system.

### Conclusion

The braking system is a critical component of a drag race car. By following the design principles outlined in this article, you can design a brake system that will help you win races.