Car Brake System Hydraulics

Introduction

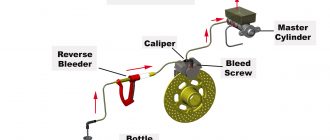

The brake system in a car is responsible for slowing down and stopping the vehicle. The hydraulic system is the component of the brake system that uses fluid to transfer pressure from the brake pedal to the brake calipers or wheel cylinders. This pressure is then used to apply the brakes and slow down or stop the car.

Components of a Hydraulic Brake System

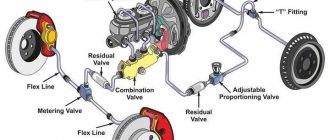

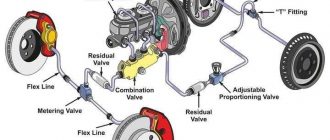

The main components of a hydraulic brake system include:

- Brake pedal: The brake pedal is the lever that the driver presses to apply the brakes.

- Master cylinder: The master cylinder is the pump that generates the hydraulic pressure to apply the brakes.

- Brake lines: The brake lines are the tubes that carry the brake fluid from the master cylinder to the brake calipers or wheel cylinders.

- Brake calipers or wheel cylinders: The brake calipers or wheel cylinders are the components that convert the hydraulic pressure into mechanical force to apply the brakes.

- Brake pads or shoes: The brake pads or shoes are the friction material that contacts the brake rotors or drums to slow down or stop the car.

How a Hydraulic Brake System Works

When the driver presses the brake pedal, the brake pedal pushes on the piston in the master cylinder. This piston pumps brake fluid from the master cylinder into the brake lines. The brake fluid then travels through the brake lines to the brake calipers or wheel cylinders.

The brake calipers or wheel cylinders convert the hydraulic pressure into mechanical force to apply the brakes. The brake pads or shoes are then forced against the brake rotors or drums, creating friction that slows down or stops the car.

Types of Hydraulic Brake Systems

There are two main types of hydraulic brake systems:

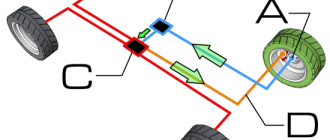

- Single-circuit brake system: In a single-circuit brake system, all four wheels are connected to the same master cylinder. If there is a leak in the brake line, all four wheels will lose brake pressure and the car will not be able to stop.

- Dual-circuit brake system: In a dual-circuit brake system, the front and rear wheels are connected to separate master cylinders. If there is a leak in one of the brake lines, the other two wheels will still have brake pressure and the car will be able to stop.

Advantages of Hydraulic Brake Systems

Hydraulic brake systems have a number of advantages over other types of brake systems, including:

- High power: Hydraulic brake systems can generate very high pressure, which allows them to stop a car quickly and efficiently.

- Reliability: Hydraulic brake systems are very reliable and can withstand a lot of wear and tear.

- Ease of maintenance: Hydraulic brake systems are relatively easy to maintain and repair.

Disadvantages of Hydraulic Brake Systems

Hydraulic brake systems also have some disadvantages, including:

- Leaks: Hydraulic brake systems can leak fluid, which can lead to a loss of brake pressure and the inability to stop the car.

- Corrosion: The components in a hydraulic brake system can corrode over time, which can weaken the system and lead to failure.

- Cost: Hydraulic brake systems can be more expensive to purchase and maintain than other types of brake systems.

Conclusion

Hydraulic brake systems are a critical component of a car’s safety system. They provide the driver with the ability to slow down and stop the car quickly and efficiently. However, hydraulic brake systems can also be complex and expensive to maintain. By understanding the components and operation of a hydraulic brake system, drivers can help to ensure that their car’s brakes are always in good working order.