Cable Car Brake System

Introduction

Cable cars are a popular mode of transportation in many cities around the world. They are often used to transport passengers over steep hills or other obstacles. Cable cars are powered by an electric motor that drives a cable, which in turn pulls the cars up the hill.

The brake system on a cable car is essential for ensuring the safety of the passengers and the crew. The brake system must be able to stop the car quickly and safely in the event of an emergency.

Types of Cable Car Brake Systems

There are two main types of cable car brake systems:

* Mechanical brakes: Mechanical brakes use friction to stop the car. The brakes are applied by a lever or pedal, which causes a brake shoe to rub against the brake drum. Mechanical brakes are simple and reliable, but they can be difficult to operate in wet or icy conditions.

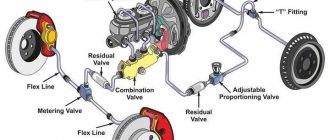

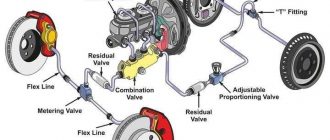

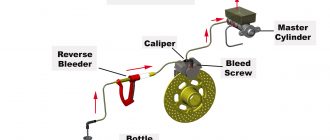

* Hydraulic brakes: Hydraulic brakes use hydraulic pressure to stop the car. The brakes are applied by a master cylinder, which sends hydraulic fluid to the brake calipers. The brake calipers then squeeze the brake pads against the brake rotors. Hydraulic brakes are more powerful than mechanical brakes, and they are easier to operate in wet or icy conditions.

Components of a Cable Car Brake System

The main components of a cable car brake system include:

* Brake shoes or pads: The brake shoes or pads are the parts of the brake system that actually stop the car. The brake shoes or pads are made of a material that is resistant to wear and tear.

* Brake drums or rotors: The brake drums or rotors are the parts of the brake system that the brake shoes or pads rub against to create friction. The brake drums or rotors are made of a metal that is strong and durable.

* Master cylinder: The master cylinder is the part of the brake system that sends hydraulic fluid to the brake calipers. The master cylinder is connected to the brake pedal.

* Brake calipers: The brake calipers are the parts of the brake system that squeeze the brake pads against the brake rotors. The brake calipers are connected to the hydraulic lines.

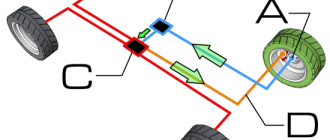

* Brake lines: The brake lines are the tubes that carry hydraulic fluid from the master cylinder to the brake calipers. The brake lines are made of a material that is resistant to corrosion.

How a Cable Car Brake System Works

When the brake pedal is pressed, the master cylinder sends hydraulic fluid to the brake calipers. The brake calipers then squeeze the brake pads against the brake rotors. This creates friction, which slows down and stops the car.

Maintenance of a Cable Car Brake System

The brake system on a cable car requires regular maintenance to ensure that it is working properly. The maintenance tasks that are typically performed on a cable car brake system include:

* Inspecting the brake shoes or pads: The brake shoes or pads should be inspected regularly for wear and tear. The brake shoes or pads should be replaced if they are worn down or damaged.

* Inspecting the brake drums or rotors: The brake drums or rotors should be inspected regularly for wear and tear. The brake drums or rotors should be replaced if they are worn down or damaged.

* Inspecting the master cylinder: The master cylinder should be inspected regularly for leaks. The master cylinder should be replaced if it is leaking.

* Inspecting the brake calipers: The brake calipers should be inspected regularly for leaks. The brake calipers should be replaced if they are leaking.

* Inspecting the brake lines: The brake lines should be inspected regularly for leaks. The brake lines should be replaced if they are leaking.

Conclusion

The brake system on a cable car is an essential safety feature. The brake system must be able to stop the car quickly and safely in the event of an emergency. The maintenance of the brake system is important to ensure that it is working properly.