Brake System Pedal Ratio for Footbrake Car

Introduction

The brake system pedal ratio is an important factor in determining the amount of force required to operate the brakes. A higher pedal ratio will result in less force required to apply the brakes, while a lower pedal ratio will result in more force required.

Factors Affecting Pedal Ratio

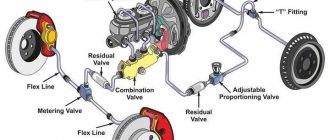

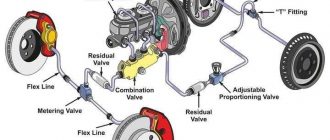

There are a number of factors that can affect the pedal ratio, including the following:

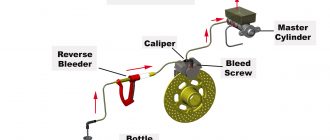

- Master cylinder size

- Wheel cylinder size

- Brake pad size

- Brake rotor size

- Leverage ratio of the brake pedal

Determining Pedal Ratio

The pedal ratio can be determined by using the following formula:

Pedal ratio = Master cylinder area / Wheel cylinder area

For example, if the master cylinder has a bore diameter of 25 mm and the wheel cylinders have a bore diameter of 40 mm, then the pedal ratio would be 25 mm2 / 40 mm2 = 0.625. This means that for every 1 unit of force applied to the brake pedal, 0.625 units of force would be applied to the wheel cylinders.

Choosing a Pedal Ratio

The ideal pedal ratio for a footbrake car will vary depending on the specific application. However, there are some general guidelines that can be followed:

- For a passenger car, a pedal ratio of 5:1 to 7:1 is typically used.

- For a light truck or SUV, a pedal ratio of 6:1 to 8:1 is typically used.

- For a heavy truck or bus, a pedal ratio of 8:1 to 10:1 is typically used.

It is important to note that the pedal ratio is just one factor that affects the amount of force required to operate the brakes. Other factors, such as the size of the brake pads and rotors, can also have a significant impact.

Conclusion

The brake system pedal ratio is an important factor to consider when designing a brake system. By understanding the factors that affect the pedal ratio, it is possible to choose a ratio that will provide the desired amount of force and feel for the application.