Brake System on American Railroad Car

Introduction

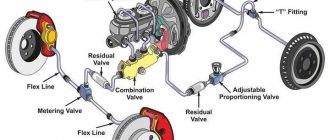

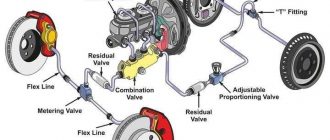

The brake system on an American railroad car is a vital safety component that allows the train crew to control the movement of the car and bring it to a stop when necessary. The brake system consists of a number of components, including the brake shoes, brake cylinders, air hoses, and air compressors.

Brake Shoes

The brake shoes are the primary component of the brake system that actually stops the wheels of the car. The brake shoes are made of a hard, durable material, such as cast iron or composite materials, and are attached to the brake beams. When the brake cylinder is activated, the brake shoes press against the wheels, creating friction that slows and stops the wheels.

Brake Cylinders

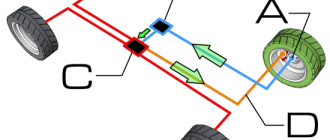

The brake cylinders are responsible for actuating the brake shoes. The brake cylinders are located on the trucks of the car and are connected to the brake shoes through a series of levers and rods. When the air pressure in the brake cylinder is increased, the brake shoes are forced against the wheels.

Air Hoses

The air hoses are used to connect the brake cylinders to the air compressor. The air hoses are made of a flexible material, such as rubber or polyurethane, and are designed to withstand the high air pressure that is used to activate the brake cylinders.

Air Compressor

The air compressor is responsible for supplying the air pressure that is used to activate the brake cylinders. The air compressor is usually located on the locomotive and is driven by the engine. The air compressor takes in air from the atmosphere and compresses it into a storage tank. When the brake cylinder is activated, the compressed air is released from the storage tank and sent to the brake cylinder.

Operation of the Brake System

The brake system is operated by the locomotive engineer. When the engineer applies the brakes, the air compressor is activated and begins to pump air into the storage tank. The compressed air is then sent to the brake cylinders through the air hoses. The brake cylinders then actuate the brake shoes, which press against the wheels and slow and stop the car.

Maintenance of the Brake System

The brake system on an American railroad car requires regular maintenance to ensure that it is functioning properly. The brake shoes should be inspected regularly for wear and tear and replaced as needed. The brake cylinders, air hoses, and air compressor should also be inspected regularly for leaks or damage.

Conclusion

The brake system on an American railroad car is a vital safety component that allows the train crew to control the movement of the car and bring it to a stop when necessary. The brake system consists of a number of components, including the brake shoes, brake cylinders, air hoses, and air compressors. The brake system is operated by the locomotive engineer and requires regular maintenance to ensure that it is functioning properly.