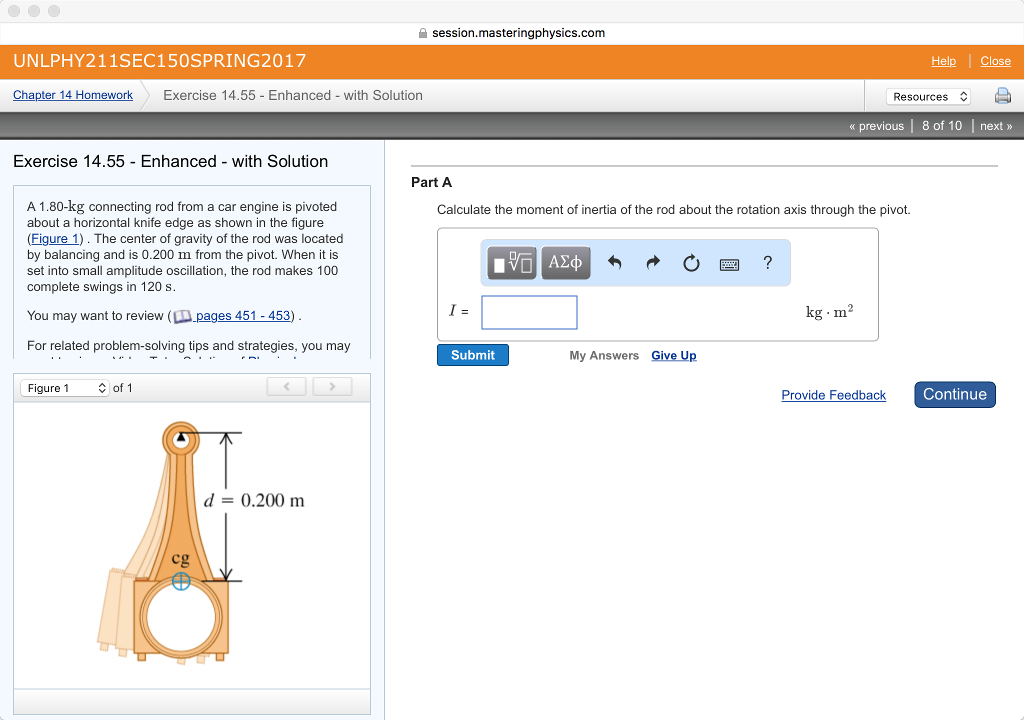

A 1.80 kg connecting rod from a car engine

A connecting rod is a part of a piston engine that connects the piston to the crankshaft. It is responsible for transmitting the force from the piston to the crankshaft, and for converting the reciprocating motion of the piston into the rotary motion of the crankshaft.

Connecting rods are typically made of forged steel or aluminum, and are designed to be strong and lightweight. They are usually I-shaped in cross-section, with a large web that connects the big end to the small end. The big end is the end that connects to the crankshaft, and the small end is the end that connects to the piston.

The connecting rod is a critical part of the engine, and its failure can cause catastrophic damage. Connecting rods are typically replaced as part of a major engine overhaul.

Connecting rod analysis

The connecting rod is a complex part, and its design is critical to the performance of the engine. The following are some of the factors that must be considered when designing a connecting rod:

- Strength: The connecting rod must be strong enough to withstand the forces that are applied to it. These forces include the force of the piston, the force of the crankshaft, and the force of the combustion gases.

- Weight: The connecting rod must be light enough to minimize the inertia of the engine. Inertia is the resistance of an object to changes in its motion. A heavy connecting rod will increase the inertia of the engine, and this will reduce the engine’s performance.

- Stiffness: The connecting rod must be stiff enough to prevent it from bending or deflecting under load. Bending or deflection of the connecting rod can cause the piston to move out of alignment with the cylinder bore, and this can lead to engine damage.

- Balance: The connecting rod must be balanced so that it does not cause the engine to vibrate. Vibration can cause the engine to run rough, and it can also lead to engine damage.

Connecting rod materials

Connecting rods are typically made of forged steel or aluminum. Forged steel is a strong and durable material, but it is also heavy. Aluminum is a lighter material than steel, but it is not as strong. However, aluminum connecting rods can be made stronger by using a process called heat treating.

The choice of material for a connecting rod depends on the specific application. For high-performance engines, forged steel connecting rods are typically used. For lighter engines, aluminum connecting rods may be used.

Connecting rod design

The design of a connecting rod is critical to its performance. The following are some of the factors that must be considered when designing a connecting rod:

- The length of the connecting rod: The length of the connecting rod affects the stroke of the engine. The stroke is the distance that the piston moves up and down in the cylinder bore. A longer connecting rod will produce a longer stroke, and this will increase the engine’s torque.

- The shape of the connecting rod: The shape of the connecting rod affects the strength and stiffness of the rod. A thicker connecting rod will be stronger and stiffer than a thinner connecting rod. However, a thicker connecting rod will also be heavier.

- The material of the connecting rod: The material of the connecting rod affects the strength, weight, and stiffness of the rod. Forged steel connecting rods are strong and durable, but they are also heavy. Aluminum connecting rods are lighter than steel connecting rods, but they are not as strong. However, aluminum connecting rods can be made stronger by using a process called heat treating.

Connecting rod failure

Connecting rods are a critical part of the engine, and their failure can cause catastrophic damage. Connecting rods can fail for a variety of reasons, including:

- Overloading: Connecting rods can fail if they are overloaded. This can occur if the engine is operated at too high a speed or if the load on the engine is too great.

- Fatigue: Connecting rods can fail due to fatigue. Fatigue is the gradual weakening of a material under repeated loading. Connecting rods are subjected to repeated loading every time the engine runs, and this can eventually lead to fatigue failure.

- Defects: Connecting rods can fail due to defects in the material or in the manufacturing process. These defects can make the connecting rod weaker and more susceptible to failure.

Connecting rod replacement

Connecting rods are typically replaced as part of a major engine overhaul. However, connecting rods may also need to be replaced if they have failed. If a connecting rod fails, it is important to have it replaced as soon as possible to prevent further damage to the engine.

Replacing a connecting rod is a complex and time-consuming process. It is important to have this work done by a qualified mechanic.